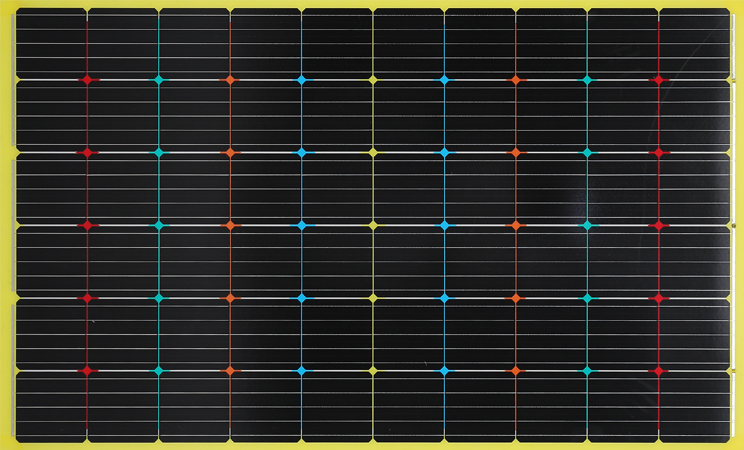

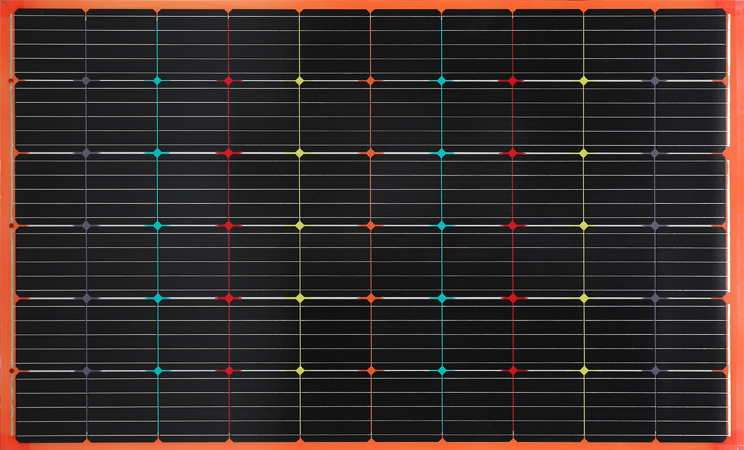

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

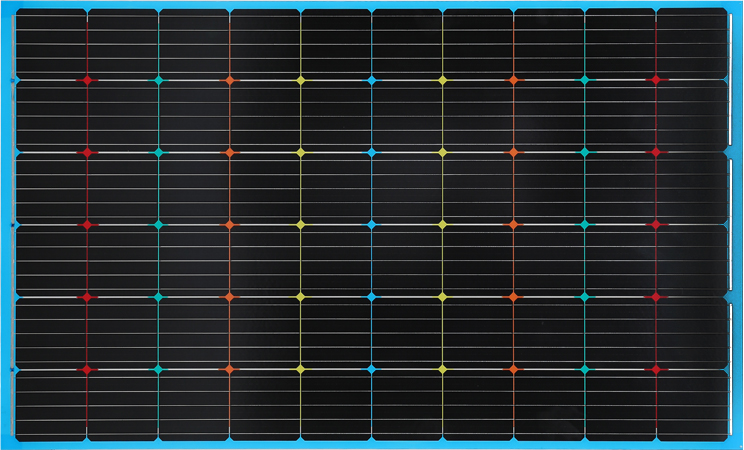

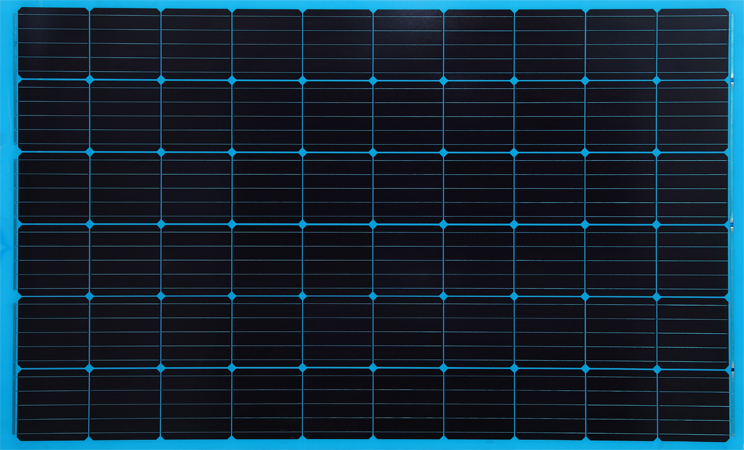

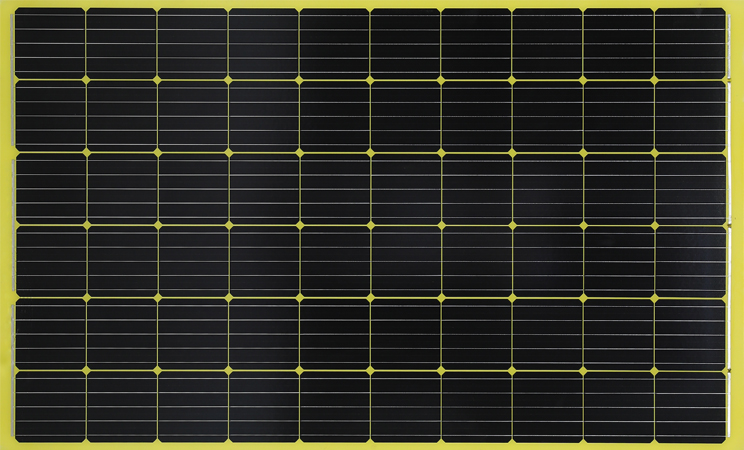

Number of cells: 72cells

We know that the raw material for making solar photovoltaic cells is monocrystalline silicon, and it is also the material for making semiconductor chips. Polycrystalline silicon is commonly known as glass. Polycrystalline silicon and monocrystalline silicon are two different substances. The application of monocrystalline solar photovoltaic panels is earlier than that of polycrystalline solar photovoltaic panels, but polycrystalline photovoltaic panels have developed rapidly later. Monocrystalline and polycrystalline are different in appearance, power conversion rate, power generation, attenuation, etc.

First of all, in appearance, monocrystalline silicon is dark blue, almost black, and polycrystalline silicon is sky blue and brightly colored. In terms of shape, the four corners of the monocrystalline cell are arc-shaped, and the polycrystalline cell is square. Furthermore, in terms of power generation, the most important factors affecting power generation are packaging, process, material, and application environment. In theory, the conversion rate of a single crystal is slightly higher than that of polycrystalline, some data show 1%, and some data show 3%. If the light is sufficient, the conversion efficiency of monocrystalline silicon is high, and the power generation is large. Under low illumination, polysilicon is more efficient. There are many factors that affect the actual power generation, and the role of conversion efficiency is smaller than most people think. Cost, the cost of a single crystal is slightly more expensive than that of polycrystalline, and the cost required by different manufacturer is different. In addition, in terms of the attenuation of objects, single crystal and polycrystalline have their own advantages, and it is impossible to distinguish the attenuation speed from the perspective of single crystal and polycrystalline. Relatively speaking, product quality, tightness, impurities, and cracks have a greater impact on attenuation.

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W