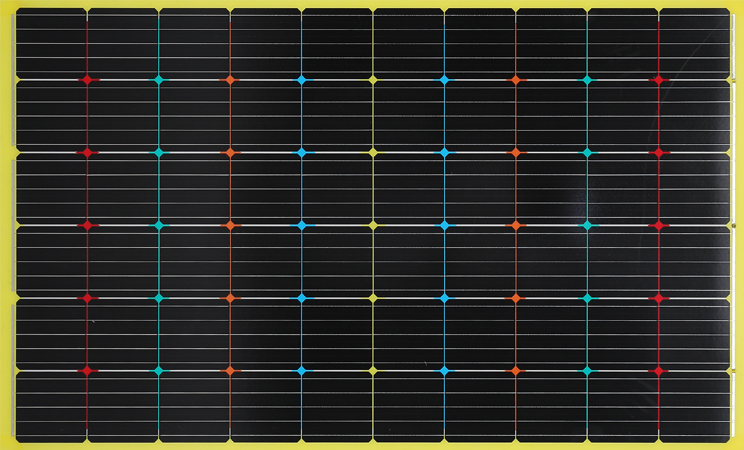

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

The production of solar cells is mainly based on semiconductor materials. Its working principle is to use photoelectric materials to absorb light energy and generate photoelectric conversion reactions. According to the different materials used, solar cells can be divided into silicon solar cells, inorganic salts such as arsenic Gallium III-V compounds, cadmium sulfide, copper indium selenium, and other multi-component compounds as materials, large solar cells prepared from functional polymer materials, nanocrystalline solar cells, etc.

Usually, crystalline silicon solar panels are made on high-quality silicon wafers with a thickness of 350-450 μm. This silicon wafer is pulled or poured to save materials. Currently, polycrystalline silicon thin-film cells are prepared by chemical vapor deposition methods, including low-pressure Chemical Vapor Deposition (LPCVD) and Plasma Enhanced Chemical Vapor Deposition (PECVD) processes. In addition, liquid phase epitaxy (LPPE) and sputter deposition methods can also be used to fabricate polysilicon thin-film cells.

In addition to the recrystallization process, the polycrystalline silicon thin film battery adopts almost all the technologies for preparing monocrystalline silicon solar cells, so that the conversion efficiency of the solar cells prepared in this way is obviously improved. Sawed from cast silicon ingots.

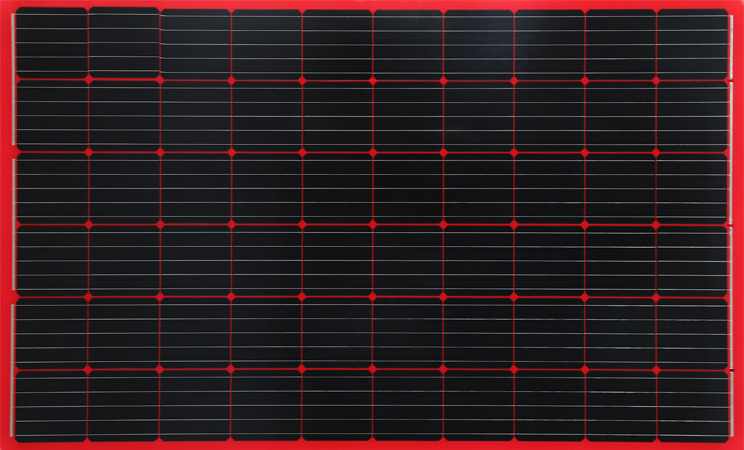

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

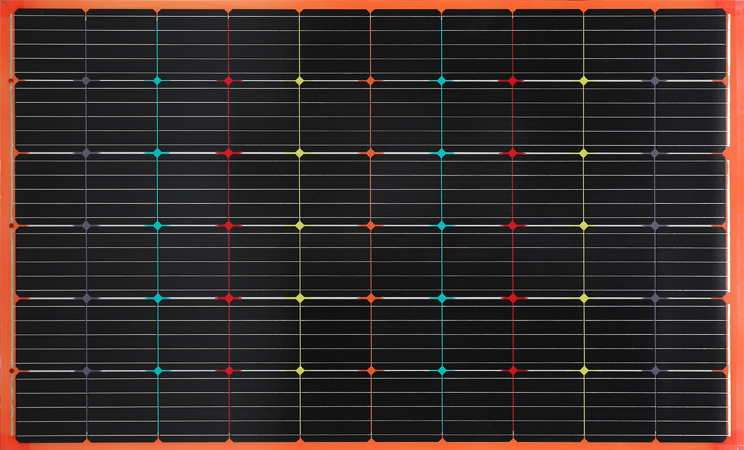

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W