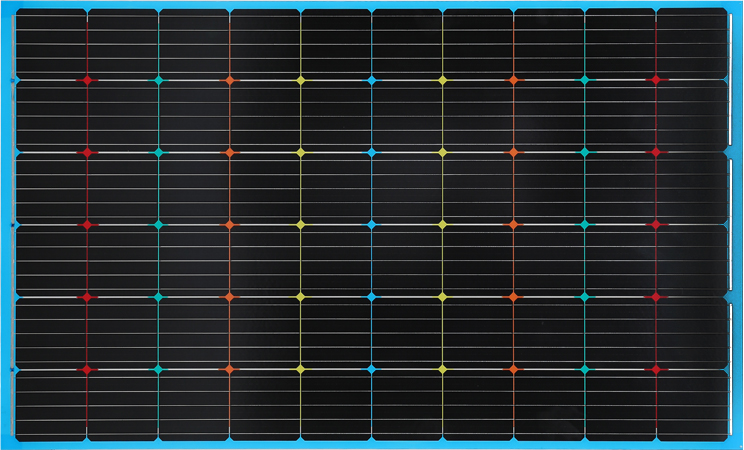

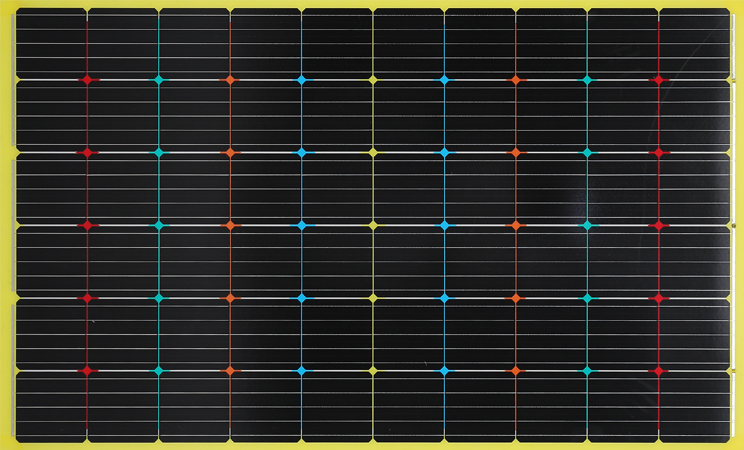

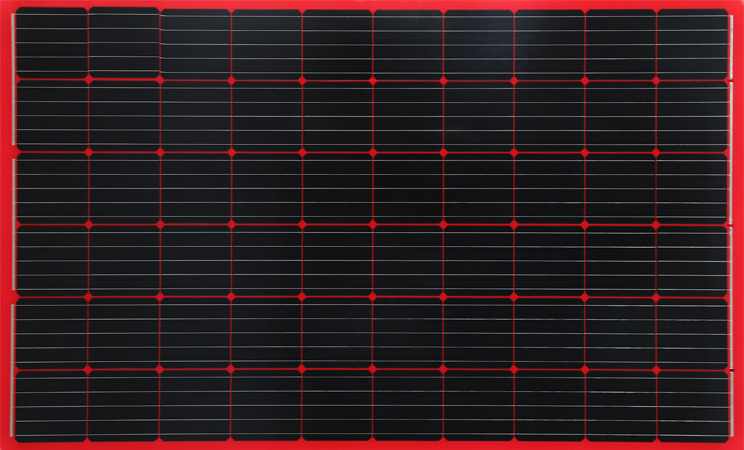

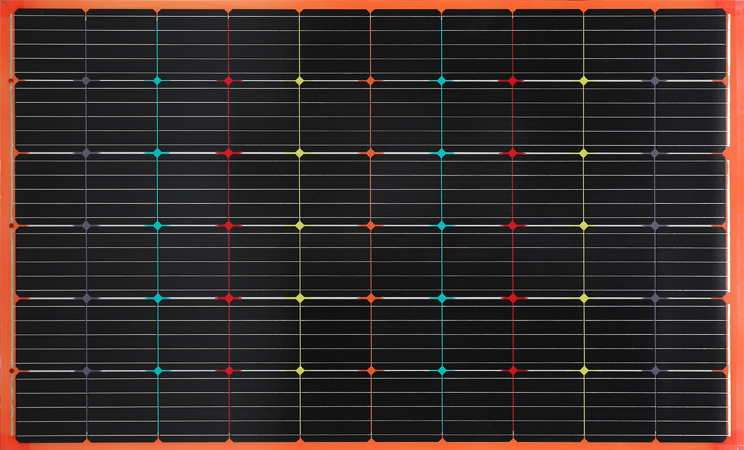

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

PVB Film began to be developed and produced in the 1920s, and is now widely used in laminated glass, which has the advantages of high transparency and impact resistance. Therefore, the construction industry, the automotive industry, and even the military (aircraft, artillery) industry also use PVB film. With the development of various industries, the requirements for PVB film are getting higher and higher, and the demand is also increasing. So how is PVB film made?

The main material of PVB film is PVB resin. Put raw materials and auxiliary materials (plasticizers, etc.) into the molding system in proportion to melt extrusion and molding, and then use pure water to cool the formed PVB film, preheat and calender and then cool, and pack into storage in slices.

In the PVB film production process, pure water is used for cooling twice to cool down and shape the product, so a large amount of cooling water is produced during the production process. Coupled with the waste water generated by daily cleaning equipment and cleaning the floor, this constitutes the PVB film waste water. The purpose of cleaning equipment is to remove part of the raw materials or incompletely reacted materials remaining in the equipment to achieve a stable material ratio and improve production quality.

These wastewater mainly contain COD, total phosphorus, ammonia nitrogen, BOD, SS and other substances, so it cannot be directly discharged into the water body, causing damage to the environment, and the wastewater must be treated by a wastewater treatment process. The following is part of the wastewater treatment process, the specific implementation is adjusted according to the actual situation.

1. Micro-electrolysis is electrolysis under low-voltage direct current conditions. It can effectively remove calcium and magnesium ions in water, thereby reducing the hardness of water. At the same time, electrolysis produces active hydrogen oxygen free radicals and active chlorine, and the adsorption on the electrode surface can also kill Dead bacteria. It is especially suitable for the pretreatment of high salt, high COD, and refractory wastewater.

2. Put in Fenton's reagent to destroy the structure of organic matter that is difficult to be degraded by organisms in the water, carry out oxidative decomposition, and effectively remove organic wastewater containing nitrobenzene and other organic waste water.

3. Biochemical treatment method, wastewater is treated by microbial degradation and the metabolism of organic matter to inorganic matter. By artificially creating an environment suitable for the survival and reproduction of microorganisms, they can reproduce and improve the efficiency of their oxidation and decomposition of organic matter. According to the types of microorganisms used, it can be divided into aerobic, anaerobic and biological enzymatic methods. The biological treatment of organic gases mainly includes biological devices and processes, such as biological filters, biological trickling filter towers, biological scrubbers, membrane bioreactors and activated sludge.

PVB film provides good adhesion and impact resistance for safety glass, bulletproof glass, windshield glass and other glass. Wastewater treatment provides companies with benefits such as cost reduction and recycling of water resources, which can better protect our water environment.

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W