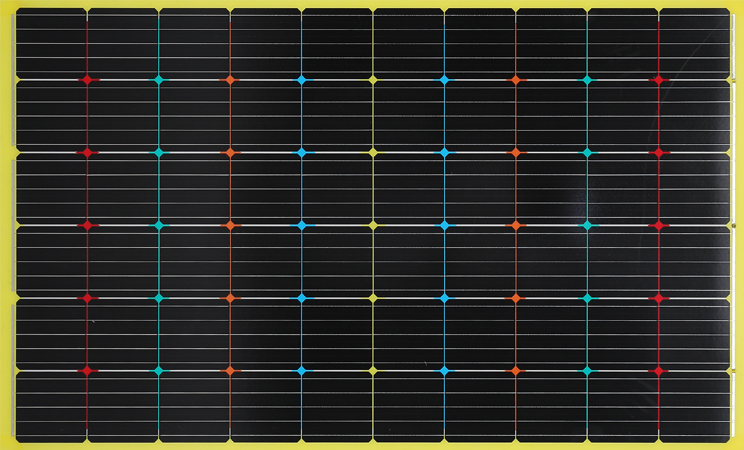

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Monocrystalline silicon is generally obtained by the Czochralski method (CZ method) on the component acquisition of photovoltaic solar panels. The single crystal seed crystal of specific crystal orientation is used for seeding, and the single crystal silicon of the target crystal orientation is obtained by rotating and pulling. The obtained product contains only one crystal grain and has the characteristics of the low defect and high conversion efficiency. At present, the conversion efficiency of large-scale production of monocrystalline silicon cells has reached 18%, but this method has high requirements for raw materials and operations and has less single feeding, high product cost, and large solar cell attenuation.

Polycrystalline silicon is mainly produced by directional solidification method. It has the characteristics of large single feeding amount, easy operation and low cost. The attenuation of the cell is much smaller than that of the monocrystalline silicon wafer. It often contains a large number of grain boundaries and defects, which makes the conversion efficiency of polycrystalline silicon solar cells about 1.5% to 2% lower than that of monocrystalline silicon cells.

The core of the quasi-single product technology is the single crystal ingot technology. Products similar to single crystal or even full single crystal produced by the ingot casting process combine the advantages of single crystal silicon and polycrystalline silicon. Compared with polycrystalline, quasi-monocrystalline silicon wafers have fewer grain boundaries and low dislocation density: the conversion efficiency of solar cells is as high as 17.5%. Compared with single crystal silicon wafers, the light-induced attenuation of quasi-single crystal cells is about 1/4~1/2 lower;

High efficiency, simple slicing process, and low cost.

The crystal orientation control, dislocation density, carbon and oxygen concentration, and impurity distribution of the silicon wafer, as well as side problems, will directly affect the cell efficiency. Different from ordinary polycrystalline, quasi-monocrystalline products are more suitable for the alkali texturing process, forming an inverted pyramid textured surface, which can significantly improve the efficiency of finished cells.

Quasi-single crystal is not only a feasible way for high-efficiency silicon wafers but also a way for ingot foundries to reduce costs. But it's not without flaws.

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

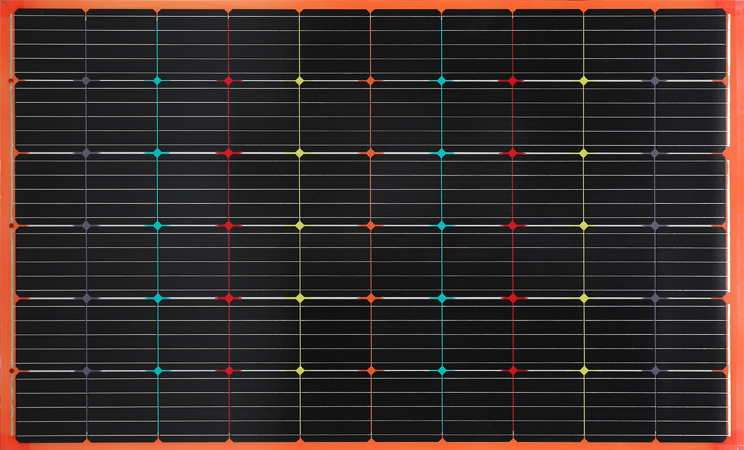

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W