PVB Film is a tough and transparent polyvinyl butyral (PVB) interlayer material used for bonding glass under heat and pressure to form laminated safety glass panels. PVB interlayer films are one of the most widely-used interlayer materials used for glass lamination applications; architectural glazings such as transportation and specialty glazings as well as applications requiring strong adhesion, impact resistance, and light visible transmittance can utilize PVB films effectively. PVB comes in various formulations, colors, and thicknesses suitable for various glass lamination needs.

PVB interlayer is often sold in sheets and used as an intermediate layer in lamination processes to produce laminated safety glass. This glass has high impact resistance that helps protect occupants of buildings and vehicles from injuries due to broken windows, as well as excellent adhesion, transparency, elasticity properties as well and the flexibility required to be formed into different shapes by molding or cutting the PVB interlayers.

The global PVB films for automobile market is expanding quickly due to an increase in usage as raw material for manufacturing safety glasses in vehicles. Major car manufacturer are rapidly adopting PVB resins into components like windshields, rear & front view mirrors, and windows - further driving demand worldwide for such films that reduce heat & noise transmission transmission.

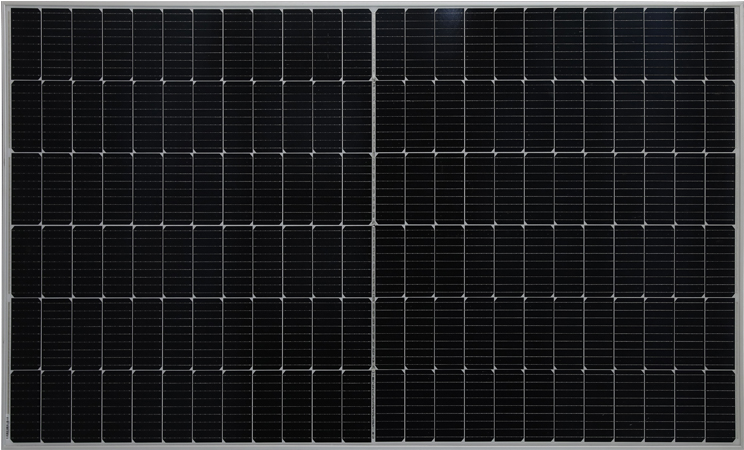

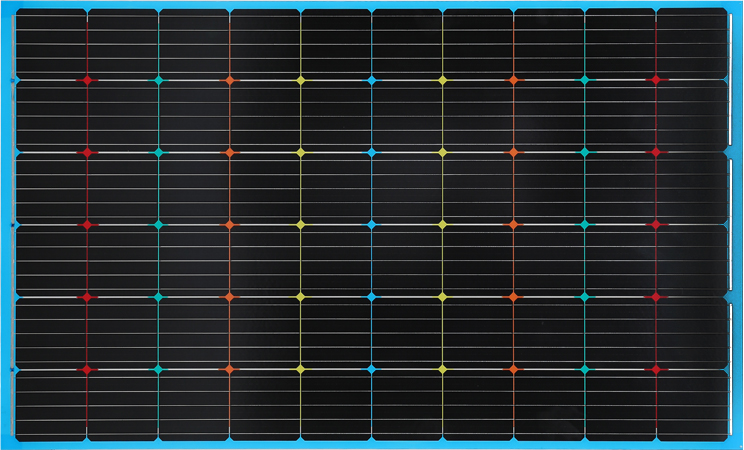

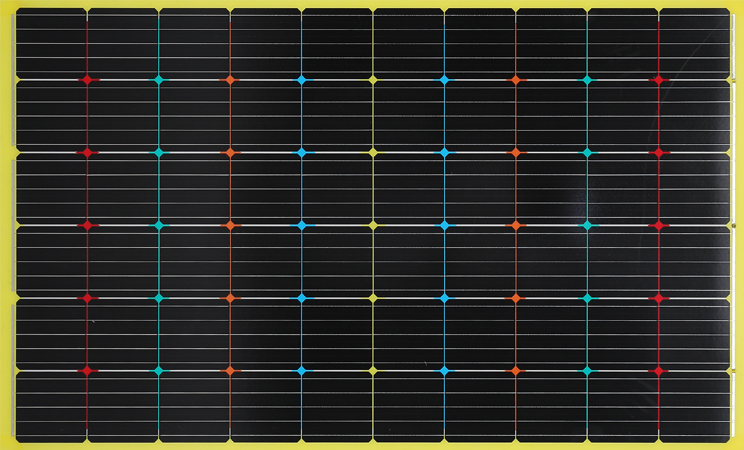

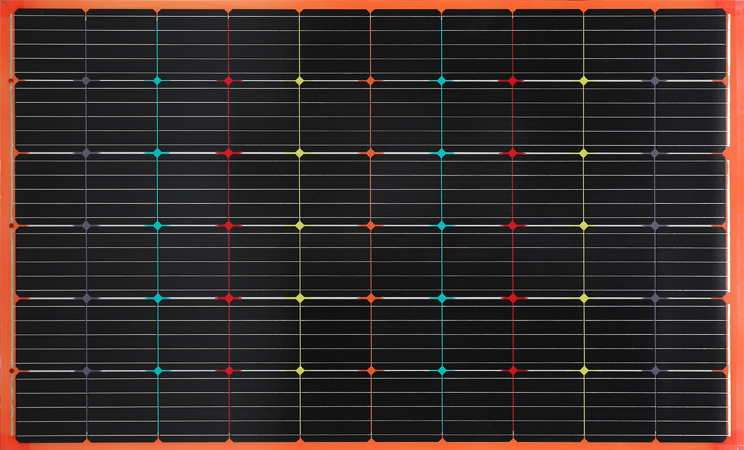

According to the report, ground transportation was the leading end-user of PVB films and sheets in 2014, accounting for more than 45%. PVB films are used as backsheets in photovoltaic modules. Meanwhile, the solar energy industry was projected as the fastest-growing end-user with compound annual growth exceeding 6% during its forecast period.

PVB film is widely utilized in the automotive industry for windshield and window production due to its strong adhesiveness, impact resistance, penetration resistance, and noise transmission reduction capabilities. Furthermore, this material offers anti-aging and UV protection properties. Market segmentation generally distinguishes two broad categories of PVB products for use - architectural and automotive grade, according to product usage. Furthermore, the automotive grade has improved impact resistance than the architectural grade.

PVB films are widely utilized in building construction, manufacturing, and industrial products such as window panes, doors, walls, and roofs. Due to its superior cost-effectiveness and performance, polyurethanes and fiberglass insulating materials have increasingly become less viable as insulation options. PVB film manufacturer are adapting by developing its chemical stability and physical properties further for increased market demand; providing advanced solutions as the years pass by.