BIPV Module is the mixing of photovoltaic additives within the building envelope to serve both as strength technology and architectural aspects. It is an alternative to traditional construction substances to keep power charges and reduce the use of fossil fuels and ozone-depleting gases.

Photovoltaic technology is reworking the design of homes and architecture, giving upward thrust to a brand new vernacular of sun architecture. Innovative architects and PV experts in lots of components of the world are integrating photovoltaics into their designs, creating new spaces that allow for the maximum technology of strength and the herbal flow of air.

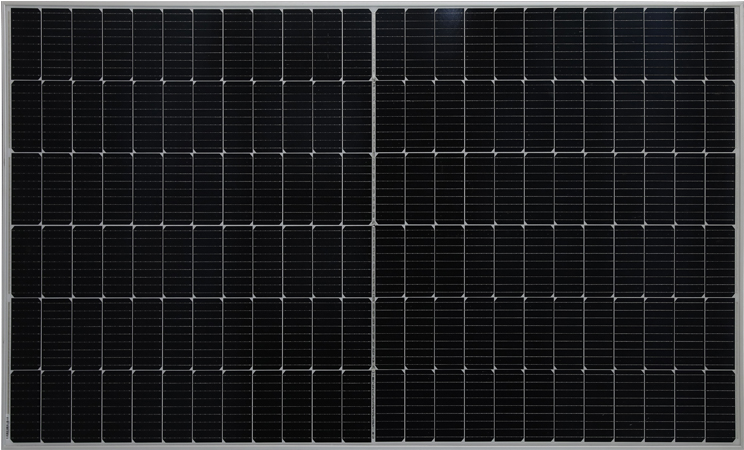

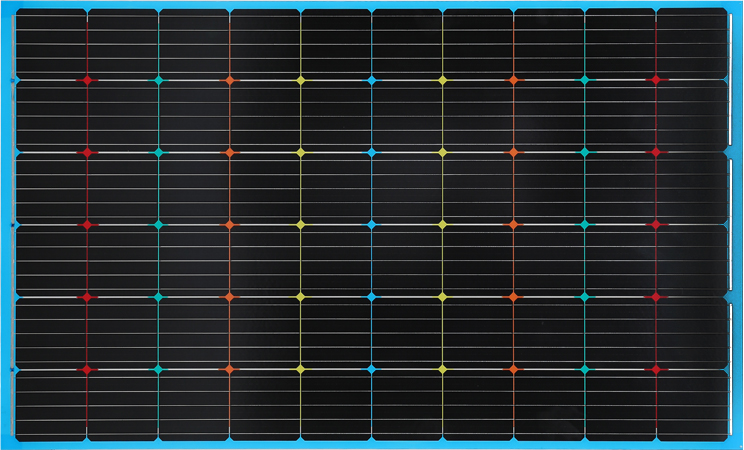

Several distinctive sorts of BIPV structures fluctuate from each other relying on the product or fabric used to lead them to and the way they're incorporated into a structure. Some of these encompass cladding and roofing systems, facades and window wall components, and curtain walls.

These structures range from a traditional in-roof machine, which utilizes applicable strips of photovoltaic cells to semi-transparent and obvious additives that may be incorporated into the architectonic composition of a roof or façade. These structures regularly employ bendy laminates and may be synthetic to suit quite several shapes, normally roof bureaucracy.

Most of these BIPV systems are primarily based on either c-Si or Thin-Film technologies. The Thin-Film merchandise has the benefit of using inherently bendy and translucent substances, which provide a big layout potential for advanced programs that require a kinetic issue.

In a BIPV system that carries thermal strength restoration, the extracted warmth is transferred to the atmosphere (air) for low-temperature applications or directly fed right into a heating and cooling device for higher temperatures. This will increase the electricity yield of the device and make it extra appropriate for a variety of packages.

It is essential to notice that maximum BIPV products require the use of inverters to convert the DC energy into AC. The inverter has precise electric DC specifications that want to be met, and if these aren't performed, the product may malfunction or even fail.

All BIPV products must be subjected to checking out and certification, whether or not they may be integrated into a roof or facade thing or as part of an in-constructing machine. UL Solutions’ safety technology leadership, enterprise knowledge, and global community position us because of the associate of preference to check and certify these products. In addition to the usual tests required for any PV product, other unique test necessities need to be met for BIPV products. For example, the insulation of a PV gadget is critical for both sturdiness and overall performance.

To comply with worldwide power and environmental requirements, all BIPV products have to be licensed by a recognized authority. UL’s BIPV certification provider gives comprehensive testing, verification, and labeling for PV products used in the construction of buildings. This includes trying out electrical parameters, durability, thermal and mechanical performance, and more.