Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

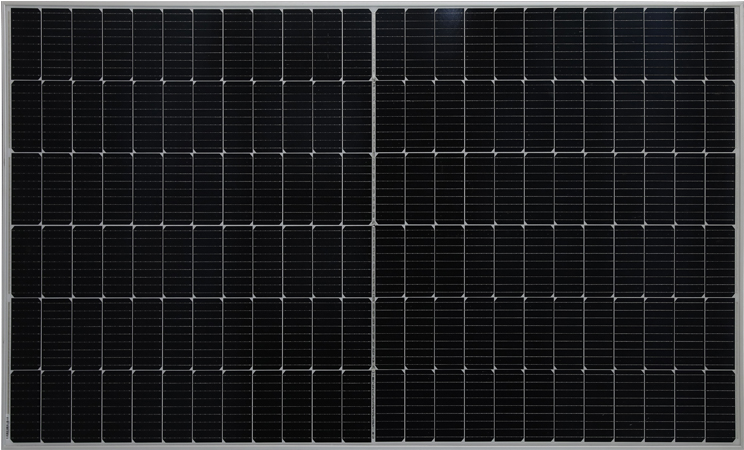

Number of cells: 72cells

Generally speaking, the interlayer in the glass used for photovoltaic solar panels on the request has three factors, videlicet EVA, POE, and PVB. These three accoutrements can be said to be different, and their operation performance in the photovoltaic assiduity is also veritably different.

As far as EVA is concerned, its advantages are low cost and high light transmission, but it has poor environmental resistance, high water vapor penetration, low impact resistance, hydrolyzed acetic acid products, etc. Because EVA double glass increases the frame, it leads to an increase in its cost.

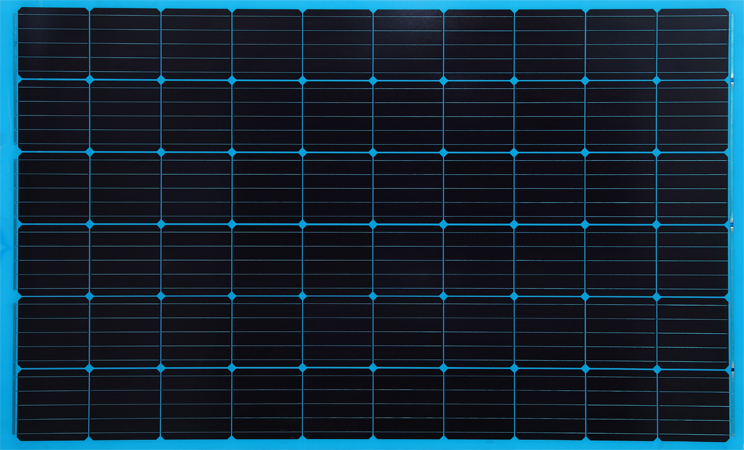

The advantages of POE lie in its high volume resistance, lower water vapor permeability than EVA, and no acetic acid products from hydrolysis, but its molecular chains are different in types, high in cost, high in fluidity, and the rearrangement of molecular chains after growing affects light transmittance.

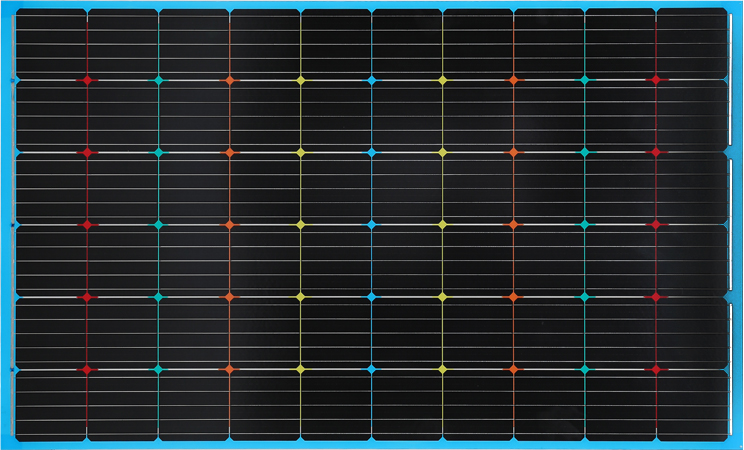

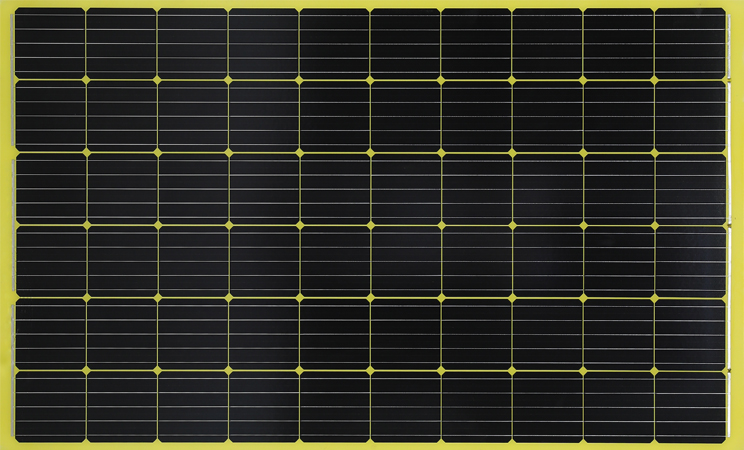

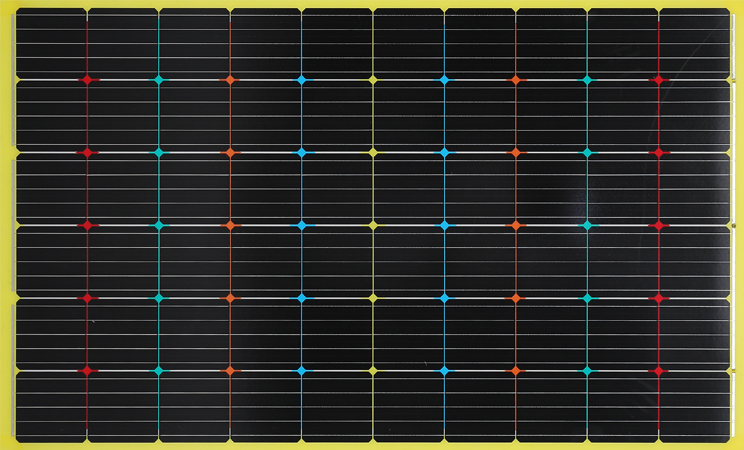

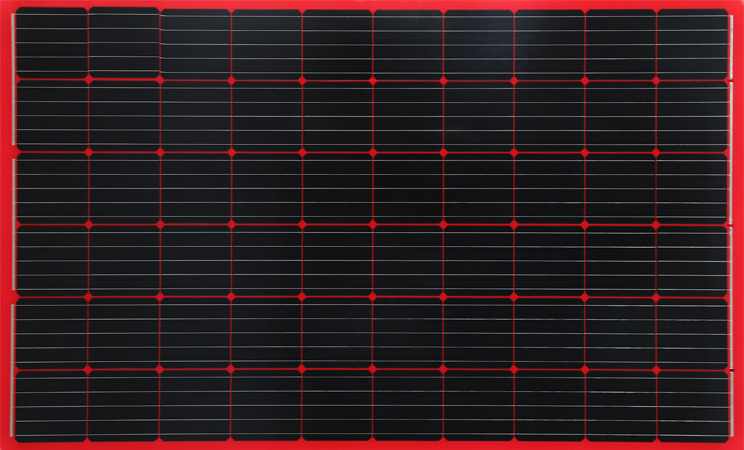

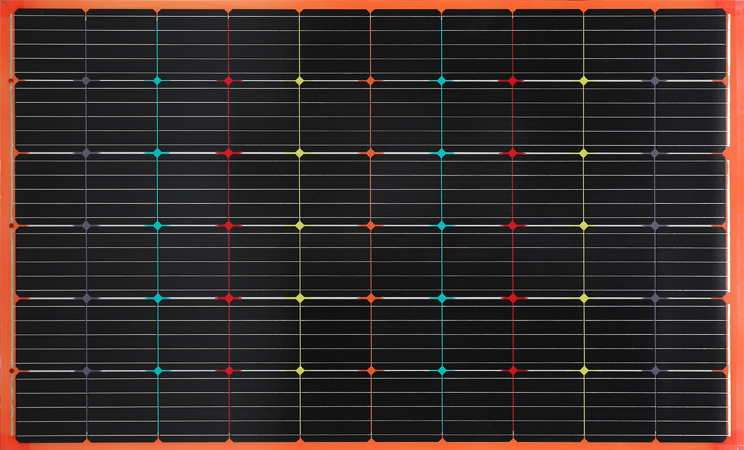

The new combination of PVB film and MBB half- chip technology, with 166 mm cell as the mainstream product, compatible with 182 mm. battery technology; rather of EVA, POE film, using PVB packaging, with excellent long-term trustability, impact resistance, and water vapor permeability, the product High safety; singly developed PVB double- glass lamination packaging process, no need for autoclave packaging, the processing technology is more effective, and the manufacturing cost is greatly reduced. Also, in order to realize colorful specifications and color customization of products, PVB film packaging of different colors is more suitable for BIPV products.

The advantages of PVB film taradiddle in its high light transmission, strong impact resistance, low water vapor penetration, strong adhesion, and reproducible processing performance, but its request cost is high, and after sweats to make its price lower than POE, it's original to EVA Likewise, the product effectiveness of its request laminator is low. On this issue, the company has cooperated with other institutions to singly develop the laminator enhancement process and reduce its lamination time to 12-18 min.

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W