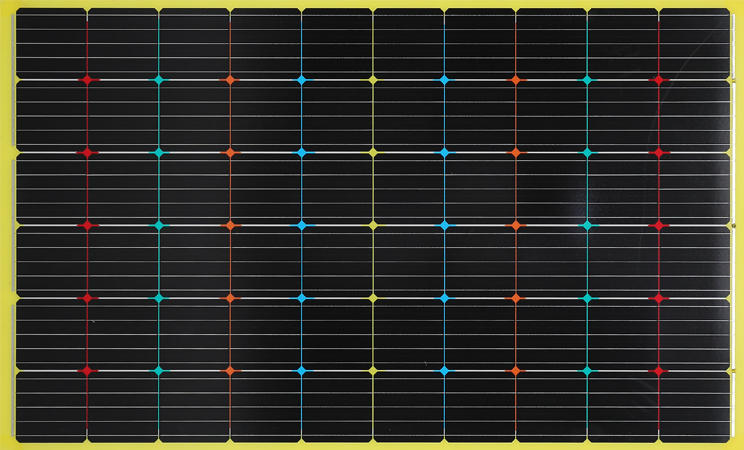

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

EVA film has good fluidity, and is suitable for wire clamping and winding operations in the film layer to make decorative glass with rich patterns, patterns and materials. As the EVA film used for laminated glass, compared with PVB or SGP, EVA has a lower melting temperature and good fluidity. Generally, it has a good processing effect at about 110 °C. Simple vacuuming and heating can meet the production needs of EVA laminated glass. EVA has good water resistance, but has average UV resistance and is prone to yellowing and aging in sunlight. At present, EVA laminated glass is mainly used for indoor partitions and decorations, and EVA is generally not suitable for outdoor curtain walls. Solar cell panels use EVA more in China, but there is a trend of using PVB film to replace EVA film in foreign countries.

PVB has high transparency, cold resistance, impact resistance and UV radiation resistance. PVB is currently the most widely used interlayer material for architectural glass and automotive glass.

Compared with EVA, the storage and processing technology of PVB interlayer is much more complicated. It is generally required that the temperature of PVB lamination is between 18-23 °C, the relative humidity is 18-23%, and the moisture content of PVB is 0.4%-0.6%. After preheating, rolling or vacuuming, it is necessary to use an autoclave at 120-130 ℃, 1.0-1.3MPa, heat preservation and pressure for 30-60 minutes.

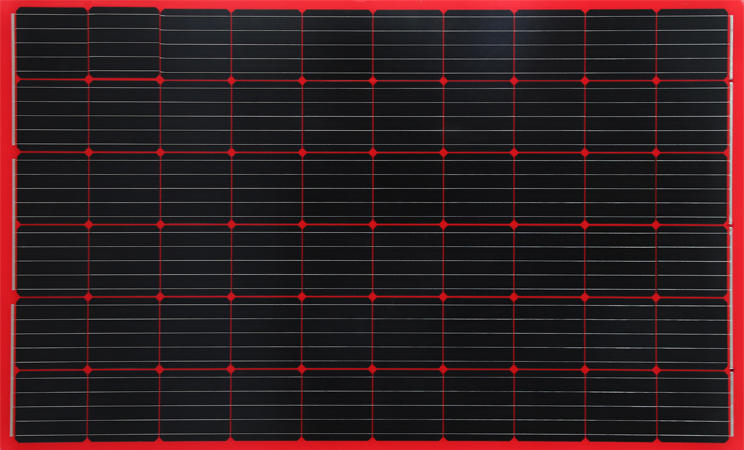

Maximum power: 440W--450W

Module conversion efficiency can reach 19.98%

Number of cells: 72cells

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

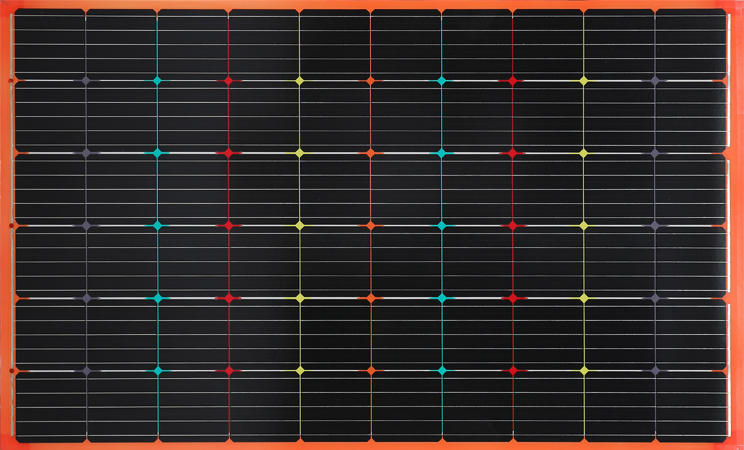

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W

Maximum system voltage: 1500V

Maximum system current: 15-16A

Tolerance range: 0~5W